SpaceX has made reaching space a hack-able endeavor where the cost has been reduced and technological evolvement has been rapid. The complexity of rocket engineering is barely trumped by any other field of engineering making them a potential candidate to be made hack-able.

Industrial Robotics needs a hack

Further advancements in Industrial Automation is expected to be highly dependent on the use of robotics to perform repeated tasks continuously and precisely. The cost of implementing industrial robotics doesn’t yet provide the required Return on Investment numbers in the context of small scale industries. Even where the cost is feasible it has not proven its ease of use as we have seen from the woes of Tesla faced in the use of robots in their assembly line.

What does a SpaceX Moment for Industrial Robotics will look like? An industrial robot that is cost-effective, safer to operate with and around humans, rapid iterations in software with over the air (OTA) updates (a Tesla moment here), ability to deploy and redeploy for varying operations.

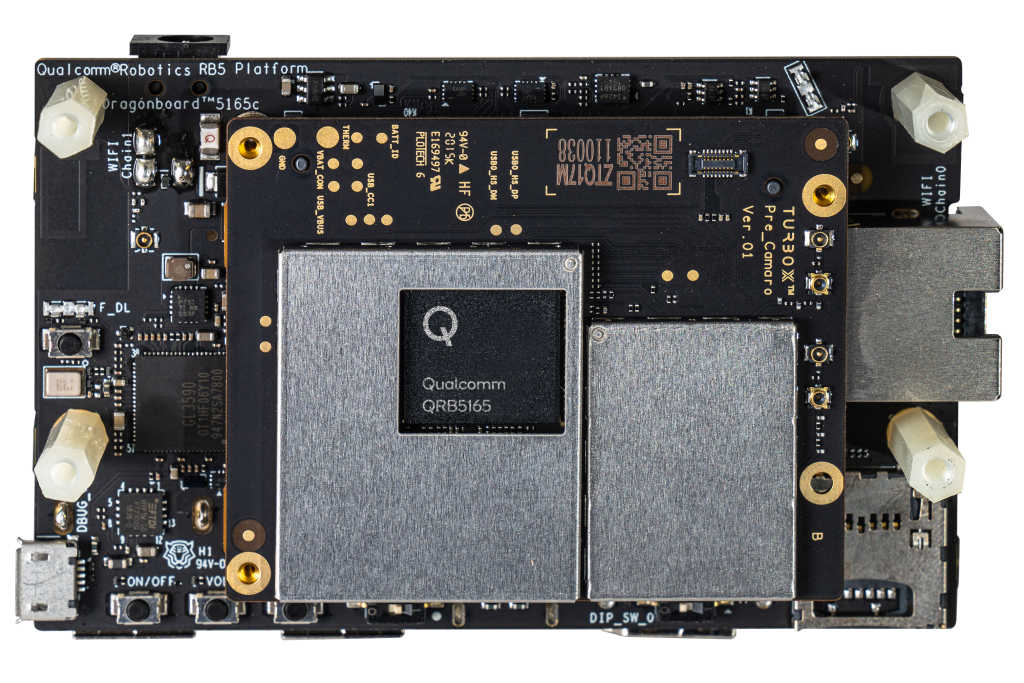

The whole inspiration behind this article is the release of Qualcomm RB5 Robotics Platform a Raspberry Pi type Single Board Computer(SBC). The integration of a powerful processor based on Snapdragon 865 chipset along with a multitude of peripherals on an SBC format opens up the development of the next generation of Industrial Robots to a community of academicians, researchers, enthusiasts, and professionals alike. Not to forget the support for both Yocto Linux and Ubuntu operating systems reducing the point of entry much further down.

Probably a “Raspberry Pi Moment” for Industrial Robotics

The RB5’s vision is enabled by a high resolution main camera, a low resolution tracking camera, a depth camera, a time of flight camera and a GSML2 camera. The ability to integrate upto 7 cameras will allow the robot to build a pretty accurate understanding of its environment while being safe around humans.

The ability to integrate with Industrial Protocols including but not limited to EtherCAT, EtherNet/IP, Modbus-TCP, and Profinet will allow the developers to easily integrate the system with the existing infrastructure. While WiFi and Bluetooth connectivity is common on most SBCs, the advantage of a Qualcomm board provides 5G and LTE connectivity making it a defacto choice for an Industrial 4.0 capability.

Banner vector created by vectorpouch – www.freepik.com